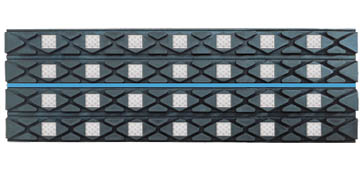

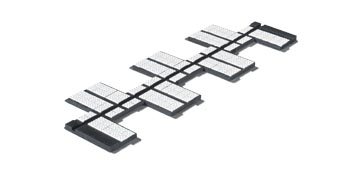

Bondable and Weld-On Pulley Lagging

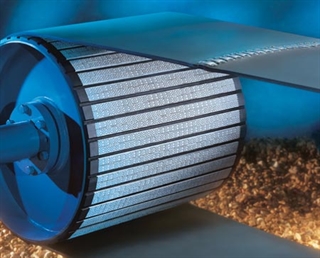

Conveyor pulley lagging is an essential part of a belt conveyor system, protecting the pulley and ensuring that there is proper friction between the pulley and the conveyor belt. When a pulley is not properly lagged, you can experience belt slippage and even increased belt wear.

Types of Pulley Lagging

Flexco offers two main types of lagging: bondable and weld-on pulley lagging. When selecting the proper pulley lagging for your application, it is important to take into account the environmental conditions around the pulley; and well as the belt condition (wet or dry); the amount of service and maintenance required for bonded lagging, as opposed to weld-on; and the expected wear life of the lagging.

Flexco offers two main types of lagging: bondable and weld-on pulley lagging. When selecting the proper pulley lagging for your application, it is important to take into account the environmental conditions around the pulley; and well as the belt condition (wet or dry); the amount of service and maintenance required for bonded lagging, as opposed to weld-on; and the expected wear life of the lagging.

If your issue is belt slippage, we have the solution. From gutterless designs that minimise vibration to products that feature the highest coefficient of friction on the market, Flexco lagging will meet the needs of your operation.

Use the filters at the left to refine your results and find the Flex-Lag® Pulley Lagging that is best suited to your application.

MINELINE®

When standard products just won't do.

Flexco Mineline® products are designed and engineered to work in some of the toughest applications in the world that test the strength and durability of your conveyor system. Products carrying the Mineline® name are proven to work — even where other products have failed.