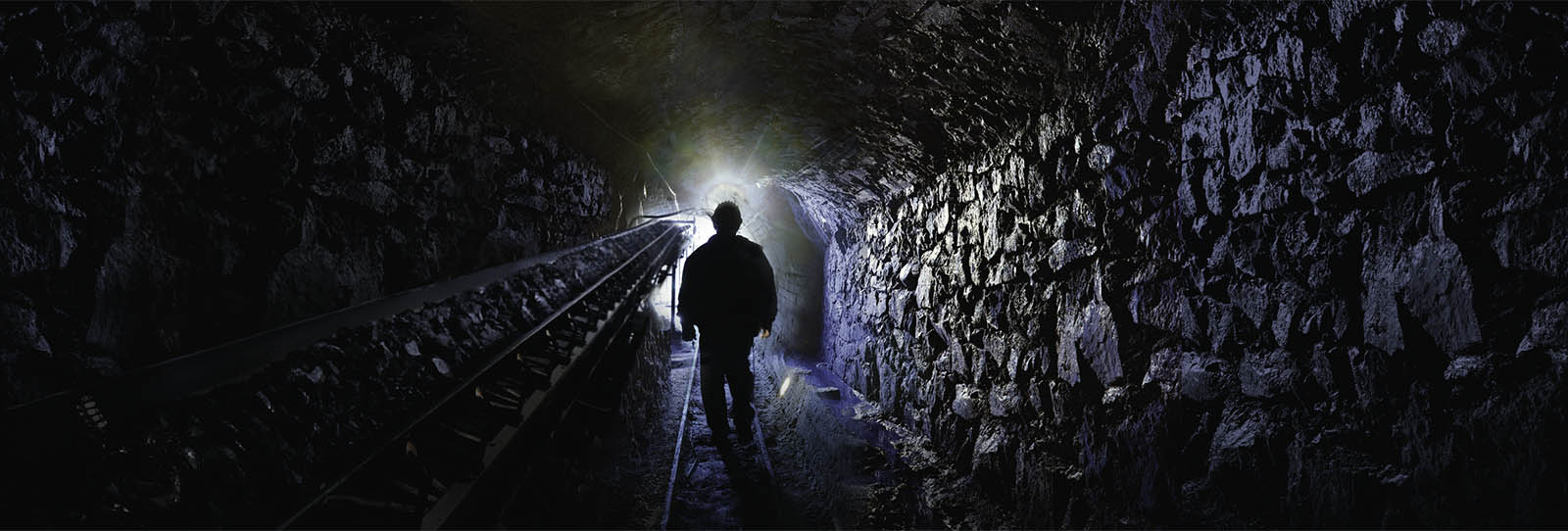

Underground Mining

Flexco knows that downtime is unacceptable in your operation, so we designed our mining solutions with easy maintenance in mind.

Flexco Understands Underground Mining

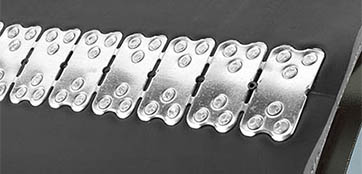

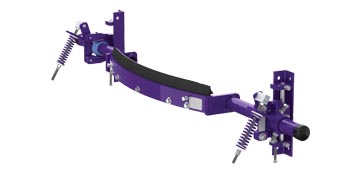

Flexco understands that one of a mine’s most valuable resource is the success of its belt conveyor system. That’s why Flexco products are designed for quick, easy installation and maintenance - to keep your belts running all day, every day. Our durable hinged fasteners can be installed either onsite or in a belt shop and pulled together with a hinge pin onsite. The flexibility of Flexco hinged fasteners also make them perfect for installation on systems with small pulleys. Our heavy-duty cleaners and trainers work to reduce carryback and keep the belt on track, reducing spillage and damage to the structure.

Flexco also knows that a mine’s other most valuable resource is its people. That’s why we’ve developed an exclusive line of belt maintenance tools with built-in safeguards. They’re specifically designed to help prevent on-the-job injuries. You don’t have to compromise safety for productivity when you partner with Flexco.

-

U.S. COAL MINING

The U.S. has produced more than 1 billion tons of coal annually for each of the last 15 years.

-

THE HEAT IS ON

The gold mines of North Eastern South Africa reach so deep underground that the rocks the miners are drilling into can reach over 150 degrees F (66 degrees C).

-

LET THERE BE LIGHT

China burns coal for 81% of its electricity, while the US uses coal for 49% of its electricity.