Mechanical Belt Fastening Systems

No matter what you’re moving, minimizing downtime and maximizing output are always top priorities—and they can be significantly affected by the way you splice your conveyor belts. Most belt conveyor operations rely on one or both common methods of splicing: mechanical belt fastening or vulcanization.

Mechanical Belt Fasteners vs. Vulcanization

Mechanical Belt Fastening is the process of joining conveyor belt ends by metal hinges or plates. Vulcanization is the process of joining belt ends through heat or chemicals.

Mechanical Belt Fastening is the process of joining conveyor belt ends by metal hinges or plates. Vulcanization is the process of joining belt ends through heat or chemicals.

The vulcanization of heavy-duty conveyor belts – whether hot or cold—is a time-consuming process that requires special skills, expensive equipment, extreme accuracy in the cutting and stripping of belt ends, and a thorough knowledge of solvents, bonding materials, and compatible cover and fill materials.

Mechanical Belt Fastening involves the use of mechanical belt fasteners (also called conveyor belt lacing). Mechanical belt fasteners combine strength and durability with affordability and easy installation.

Heavy-Duty Belt Fastener Types

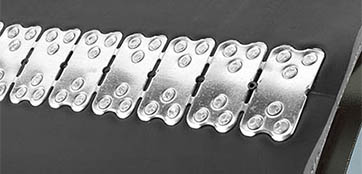

In heavy-duty applications like coal, cement, mining, and aggregate, there are two main belt fastener types: Hinged Plate and Solid Plate. Hinged plate fasteners, often used with small pulleys, are installed into each end of the belt and then joined together and held in place with a pin. Solid plate fasteners consist of one plate that is installed into both ends of the belt and fastened together. Solid plate fasteners are used with larger pulleys and for applications that require a sift-free splice. These fasteners are installed into the belt using bolts, rivets, or staples (depending on belt type and application) and are available in a variety of metals.

In heavy-duty applications like coal, cement, mining, and aggregate, there are two main belt fastener types: Hinged Plate and Solid Plate. Hinged plate fasteners, often used with small pulleys, are installed into each end of the belt and then joined together and held in place with a pin. Solid plate fasteners consist of one plate that is installed into both ends of the belt and fastened together. Solid plate fasteners are used with larger pulleys and for applications that require a sift-free splice. These fasteners are installed into the belt using bolts, rivets, or staples (depending on belt type and application) and are available in a variety of metals.

![]() Heavy Duty

Heavy Duty

Mechanical Belt Fastener

Selection Calculator

Light-Duty Belt Fastener Types

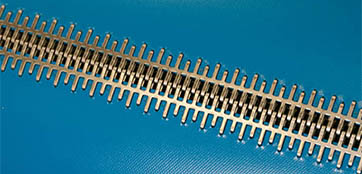

In light-duty applications like agriculture, parcel handling, food, and laundry, fasteners are available in hook and lacing styles, are installed into both ends of the belt, and are joined together with a hinge pin. Installation methods vary from machine application to using hand tools, and the fasteners are available in a variety of metals, plastics, and in some cases, food-grade materials.

In light-duty applications like agriculture, parcel handling, food, and laundry, fasteners are available in hook and lacing styles, are installed into both ends of the belt, and are joined together with a hinge pin. Installation methods vary from machine application to using hand tools, and the fasteners are available in a variety of metals, plastics, and in some cases, food-grade materials.

Choosing the proper mechanical belt fastening system is one of the most important steps in splicing a belt.

Use the filters at the left to refine your results and find the mechanical belt fastening system that is best suited to your application.

MINELINE®

When standard products just won't do.

Flexco Mineline® products are designed and engineered to work in some of the toughest applications in the world that test the strength and durability of your conveyor system. Products carrying the Mineline® name are proven to work — even where other products have failed.